Your Complete

Packaging Partner

From idea to delivery, JPI provides end-to-end packaging solutions that combine speed, precision, and innovation — tailored to your business needs.

Our Product Expertise

- Materials

- Bottles & Containers: LDPE, HDPE, PP

- Caps & Closures: HDPE, PP

- Insert : LDPE

- Sizes / Capacity

- Small: 25–100 ml (Customizable)

- Medium: 100 ml–1 L(Customizable)

- Large: 1–4 L (Customizable)

- Shapes & Designs

- Round, Oval, Square, Rectangular, Curved bottles

- Features / Caps & Closures

- Tamper-evident caps & bands

- Leak-proof design

- Transparent, opaque, colored, and glossy surface options

- Lightweight & ergonomic for easy handling

- Induction Seal: Ensures product safety and freshness

- Barrier Properties: Oxygen and moisture barrier for sensitive products

- Common Cap & Closure Types:

- Standard Caps

- Screw Caps

- Flip-Top Caps

- Snap-On Caps

- Press-On Caps

- Decoration Methods

- Hot Foil Stamping – Metallic finishes (gold, silver) for a premium appeal

- Stickers – High-quality stickers for branding

- Branding Elements

- Embossing / Debossing: Raised or recessed logos for a premium feel

- Custom Mold Design: Ergonomic, curved, or slender bottles for brand differentiation

- Color Masterbatch: Custom colors to strengthen brand identity

- Cap Decoration: Printed logos, metallic bands

- Labels & Stickers: Paper, PP, HDPE options with glossy/matte lamination, waterproof available

- Safety & Compliance

- Certifications: HACCP, FSSC 22000 V6, ISO 22000:2018, ISO 9001:2015, SMETA 4-Pillars

- Functional Testing: Leak-proof, drop test, UV-blocking, chemical compatibility, swab testing, Scuff & Abrasion Testing, Top load testing for bottle

- Eco Options

- Recyclable materials: LDPE , HDPE, PP

Technologies

Injection Molding, Blow Molding, Injection Blow Molding, Flexographic Printing, Offset Printing, Letterpress Printing, Silk Screen Printing, In-Mould Labelling (IML), ABL Tube Manufacturing, PBL Tube Manufacturing

- Materials

- Bottles & Containers: HDPE,PP

- Caps & Closures: LLDPE,LDPE,HDPE, PP

- Insert : LDPE

- Sizes / Capacity

- Small: 50 g–100 g (Customizable)

- Medium: 100 ml–1 L / 100 g–1 kg (Customizable)

- Large: 1–20 L / 1 kg–20 kg (Customizable)

- Shapes & Designs

- Round, Oval, Square, Rectangular, Thin-wall

- Features / Caps & Closures

- Tamper-evident caps & bands

- Leak-proof design

- Transparent, opaque, colored, and glossy surface options

- Lightweight & ergonomic for easy handling

- Stackable and nestable for transport efficiency

- Induction Seal: Ensures product safety and freshness (Aluminum seal induction wad, EP)

- Barrier Properties: Oxygen and moisture barrier for sensitive products

- Common Cap & Closure Types:

- Screw Caps

- Heat-Sealed Foil Lids (Induction/Aluminum Foil)

- Decoration Methods

- In-Mold Labeling (IML): Durable, premium look

- Stickers: High-quality branding options

- Branding Elements

- Embossing / Debossing: Raised or recessed logos for a premium feel

- Custom Mold Design: Ergonomic, curved, or slender bottles for brand differentiation

- Color Masterbatch: Custom colors to strengthen brand identity

- Cap Decoration: Printed logos, metallic bands

- Labels & Stickers: PP, HDPE options with glossy/matte lamination with Light fastness.

- Safety & Compliance

- Certifications: HACCP, FSSC 22000 V6, ISO 22000:2018, ISO 9001:2015, SMETA 4-Pillars

- Functional Testing: Leak-proof, drop test, UV-blocking, chemical compatibility, swab testing, air quality , Scuff & Abrasion Testing

- Eco Options

- Recyclable materials: LDPE , HDPE, PP

Technologies

Injection Molding, Blow Molding, Injection Blow Molding, Flexographic Printing, Offset Printing, Letterpress Printing, Silk Screen Printing, In-Mould Labelling (IML), ABL Tube Manufacturing, PBL Tube Manufacturing

- Materials

- Bottles & Containers: HDPE, PP

- Caps & Closures: LDPE, HDPE, PP

- Sizes / Capacity

- Small: 10 ml–100ml / 4–45 g (Customizable)

- Medium: 100ml-1L (Customizable)

- Large: (Customizable)

- Shapes & Designs

- Round

- Features / Caps & Closures

- Tamper-evident caps & bands

- Leak-proof design

- Transparent, opaque, colored, and glossy surface options

- Lightweight & ergonomic

- Stackable and nestable

- Induction Seal: Ensures product safety and freshness

- Barrier Properties: Oxygen and moisture barrier

- Common Cap & Closure Types:

- Induction-Sealed Foil Lids / Wads

- Snap-On Caps

- Child-Resistant Lids (CR Caps)

- Measuring Cup Lids

- Temper proof Cap

- Branding Elements

- Embossing / Debossing: Raised or recessed logos for a premium feel

- Custom Mold Design: Ergonomic, curved, or slender bottles for brand differentiation

- Color Masterbatch: Custom colors to strengthen brand identity

- Cap Decoration: Printed logos, metallic bands

- Labels & Stickers: PP, HDPE options with glossy/matte lamination with Light fastness.

- Safety & Compliance

- Certifications: HACCP, FSSC 22000 V6, ISO 22000:2018, ISO 9001:2015, SMETA 4-Pillars

- Functional Testing: Leak-proof, drop test, UV-blocking, chemical compatibility

- Eco Options

- Recyclable materials: LDPE , HDPE, PP

Technologies

Injection Molding, Blow Molding, Injection Blow Molding, Flexographic Printing, Offset Printing, Letterpress Printing, Silk Screen Printing, In-Mould Labelling (IML), ABL Tube Manufacturing, PBL Tube Manufacturing

- Materials

- Bottles & Containers: HDPE, PP

- Caps, Lids & Closures: HDPE, PP

- Others: Polycarbonate, ABS, GPPS, TPE

- Sizes / Capacity

- Medium: 1 L–4 L

- Large: 5 L–20 L

- Shapes & Designs

- Round, Oval, Square, Rectangular, Flat-wall

- Features / Caps & Closures

- Tamper-evident caps & bands

- Leak-proof design

- Transparent, opaque, colored, and glossy surface options

- Lightweight & ergonomic

- Stackable and nestable

- Barrier Properties: Oxygen and moisture barrier

- Common Cap & Closure Types:

- Snap-On Caps

- Flip-Top Caps

- Snap-On Caps / Press-On Caps

- Decoration Methods

- In-Mold Labeling (IML)

- Stickers: High-quality branding

- Branding Elements

- Embossing / Debossing: Raised or recessed logos for a premium feel

- Custom Mold Design: Ergonomic, curved, or slender bottles for brand differentiation

- Color Masterbatch: Custom colors to strengthen brand identity

- Cap Decoration: Printed logos, metallic bands

- Labels & Stickers:PP, HDPE options with glossy/matte lamination with Light fastness

- Safety & Compliance

- Certifications: HACCP, FSSC 22000 V6, ISO 22000:2018, ISO 9001:2015, SMETA 4-Pillars

- Functional Testing: Leak-proof, drop test, UV-blocking, chemical compatibility, Scuff & Abrasion Testing

- Eco Options

- Recyclable materials: LDPE , HDPE, PP

Technologies

Injection Molding, Blow Molding, Injection Blow Molding, Flexographic Printing, Silk Screen Printing, In-Mould Labelling (IML), ABL Tube Manufacturing, PBL Tube Manufacturing

- Materials

- Chick Feed Tray: PP

- Chick Drinker: HDPE, PP

- Egg Tray: HDPE

- Sizes / Capacity

- Drinker Bottles: 1–9 L

- Shapes & Designs

- Round, Square

- Features / Caps & Closures

- Transparent, opaque, colored, and glossy surface options

- Lightweight & ergonomic

- Stackable and nestable

- Branding Elements

- Embossing / Debossing: Raised or recessed logos for a premium feel

- Custom Mold Design: Ergonomic, curved, or slender bottles for brand differentiation

- Color Masterbatch: Custom colors to strengthen brand identity

- Safety & Compliance

- Certifications: HACCP, FSSC 22000 V6, ISO 22000:2018, ISO 9001:2015, SMETA 4-Pillars

- Functional Testing: Leak-proof, drop test, UV-blocking, chemical compatibility

- Eco Options

- Recyclable materials: HDPE, PP, LDPE

Technologies

Injection Molding, Blow Molding, Injection Blow Molding

Our Process From Idea to Shelf

From concept to delivery, our streamlined process ensures speed, precision, and quality at every stage giving you packaging solutions that are as reliable as they are innovative.

01

Concept & Design

R&D, engineering, and marketing teams work together to create functional, market-ready packaging tailored to your brand.

02

Mold Design & Fabrication

In-house mold-making ensures precision, customization, and reduced lead times.

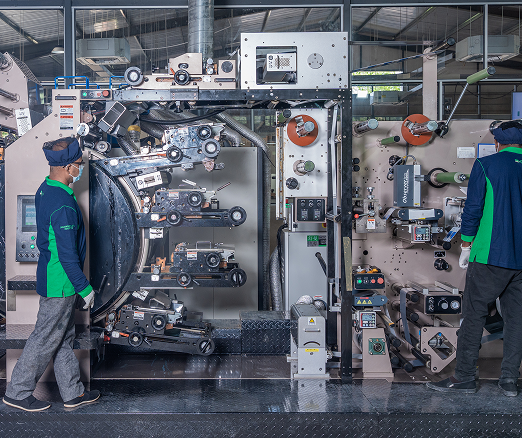

03

Production Excellence

Advanced technologies — Injection Molding, Blow Molding, In-Mold Labelling, and more — deliver consistent quality and flexibility.

04

Branding & Labelling

High-quality printing and finishes that strengthen brand visibility and shelf impact.

05

Packaging & Delivery

Secure, timely delivery with flexible scheduling to fit your supply chain.

Industries We Serve

Industries We Serve

Established in 1990s

Pharmaceutical

Our pharmaceutical packaging ensures product safety, precision, and compliance. From child-resistant caps to tamper-proof seals, we support quality, trust, and care in every dose.

Food & Beverage

Our food and beverage packaging is built to keep products fresh, safe, and appealing on the shelf. With options like leak-proof bottles, microwave-safe trays, and tamper-evident caps, we help brands deliver convenience and confidence to their customers.

Personal Care

For personal care and cosmetics, packaging is about both function and style. We design bottles, jars, and dispensers that are practical, durable, and visually striking , helping brands stand out while ensuring ease of use and product protection.

Industrial

Our industrial packaging solutions are engineered for strength and reliability. From heavy-duty containers to stackable jerry cans, we create packaging that can withstand demanding environments while ensuring safety and efficiency.

Our Competitive Edge

In-House Mold Fabrication

Reduces lead time from concept to market.

Reduces lead time from concept to market.

Ensures precision, functionality, and aesthetic appeal.

Market Insight

We identify customer needs even when they are not fully defined, transforming ideas into tangible, market-ready products.

Proven Track Record

Decades of experience in delivering high-quality, reliable packaging across diverse industries.

Have a project in mind or need customized packaging solutions?