Global manufacturing is advancing rapidly and packaging now plays a key role in ensuring product safety, sustainability, and compliance. Brands expanding across borders must meet evolving international standards that reflect both environmental responsibility and technical excellence.

At JPI, we support that journey with confidence and care. As a trusted plastic company in Sri Lanka, we combine certified systems, responsible engineering, and advanced technology to produce packaging that meets global benchmarks for quality and reliability.

Our products are trusted by leading local and multinational brands including Nippon Paint, Nestlé, Haleon, Unilever and Pyramid Wilmar Pvt Ltd, whose exports depend on consistent, compliant, and durable packaging solutions.

According to the International Organization for Standardization (ISO), quality management systems strengthen manufacturing consistency and competitiveness by standardizing processes, reducing errors, and improving reliability. This principle defines how JPI operates helping brands achieve compliance, trust, and long term value in every batch we produce.

Adapting to Evolving Regulations

Global packaging regulations are changing rapidly, with increasing emphasis on sustainability, safety and traceability. JPI’s manufacturing systems are built to adapt quickly to these shifts.

Our certified production processes ensure that all materials, molds, and manufacturing steps align with both local and international regulatory frameworks. This adaptability allows our clients to enter new markets without operational disruptions.

Strength Through Certified Systems

Certification is the foundation of our global readiness. We maintain ISO 9001:2015 for quality management, ISO 22000:2018 for food safety and FSSC 22000 for rigid plastic packaging.

These systems ensure that every batch produced meets the highest levels of traceability and accountability, giving international buyers confidence in both product performance and process integrity.

Eco Conscious Engineering

Sustainability is central to our engineering philosophy. JPI prioritizes virgin-grade recyclable materials, efficient mold designs, and waste reduction throughout production.

We also incorporate in-mold labeling (IML) technology, which supports recyclability and reduces material contamination. This eco conscious approach ensures that our packaging not only meets performance standards but also supports circular economy principles valued by global markets.

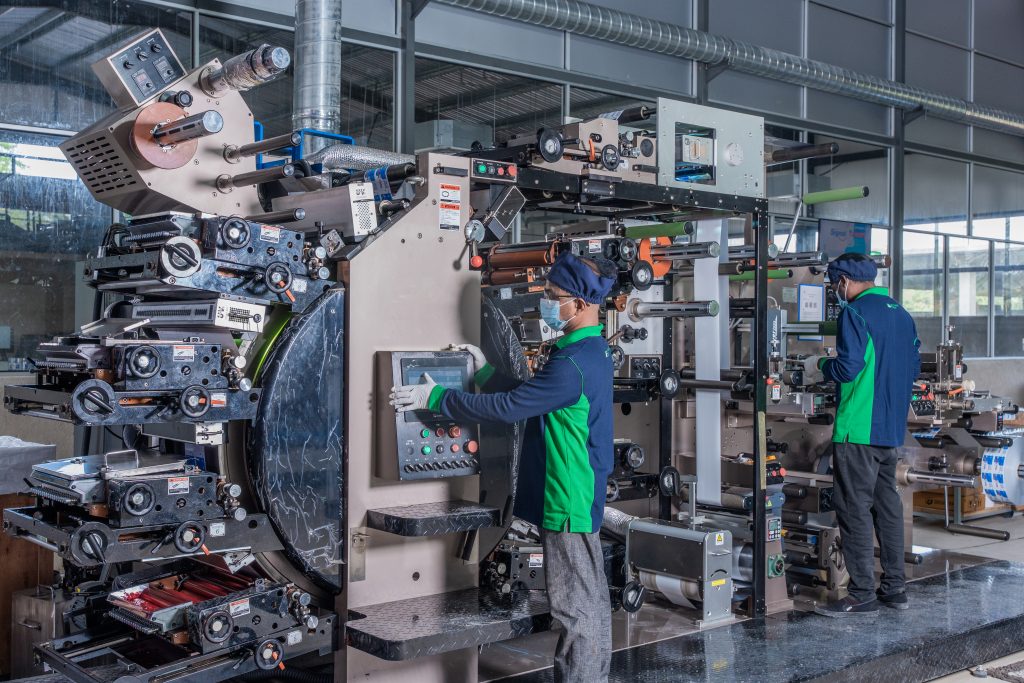

Technology Enhancing Reliability

Advanced technology drives precision and consistency. Our automated monitoring systems and real-time production tracking ensure accuracy at every stage of manufacturing.

These systems allow JPI to maintain identical quality standards across high-volume production runs, ensuring that every order performs reliably in transit, storage, and use.

Building a Future of Trust and Compliance

Achieving global standards is not a one-time milestone but a continuous commitment. At JPI, we combine certified systems, sustainable innovation, and people-driven excellence to help brands grow beyond borders.

As a leading plastic company in Sri Lanka, our goal is to help businesses meet the world’s toughest requirements with products that reflect both precision and purpose.

Are you looking for a partner who understands the path to global readiness?