In the pharmaceutical industry, packaging is never just about convenience; it’s about compliance, safety, and trust. Every tube and plastic bottle must meet strict regulations to protect the product inside and ultimately, the patients who depend on it. That’s why pharmaceutical grade tubes go through a carefully controlled process, from material sourcing to final sealing, to ensure they meet the highest standards.

At JPI , we create packaging solutions designed for regulated industries, giving pharma clients the confidence that their products are safe, compliant, and ready for market.

Raw Material Selection

It starts with selecting the right materials. We use only medical grade plastics approved for sensitive pharmaceutical applications. Every plastic bottle and tube is manufactured from materials free of harmful additives and engineered for stability, ensuring products remain safe and effective throughout their shelf life.

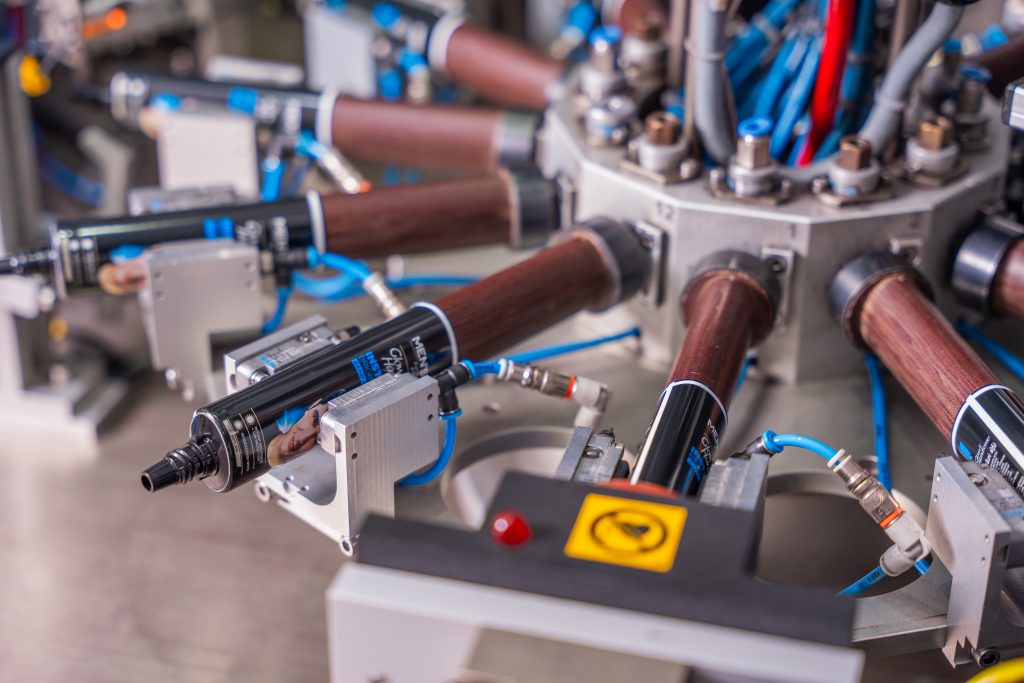

Cleanroom Standards and Sealing

Pharmaceutical packaging must be produced in controlled environments. At JPI, our facilities operate under strict cleanroom conditions that reduce the risk of contamination. With advanced sealing technology, every tube we make is airtight, leak-proof, and compliant with international safety requirements whether it’s for ointments, gels, or topical treatments.

Traceability and Quality Checks

Accountability is non-negotiable in pharma. That’s why we run rigorous quality control (QC) checks at every stage of production. From extrusion to final packing, every batch is traceable with lot numbers and documentation, giving procurement teams and regulators full transparency.

Moisture and Light Resistance

Pharmaceutical products are highly sensitive to the environment. Our tubes are engineered with barrier protection that shields contents from both moisture and light. This helps preserve the stability and safety of formulations, ensuring patients receive medicines exactly as intended.

Why It Matters for Pharma Clients

In this sector, compliance isn’t optional, it’s everything. By choosing JPI, pharmaceutical brands get packaging backed by strong quality management systems, including ISO 9001:2015 certification, and practices designed to align with global regulatory expectations. The result is packaging that safeguards both the product and the reputation of the brand behind it.

Are you looking for pharmaceutical packaging in Sri Lanka?

At JPI, we deliver pharma-grade tubes and plastic bottles with the precision, compliance, and reliability that regulated industries demand.

Contact us today to explore packaging solutions tailored to your pharmaceutical needs