By 2026, brands operating in FMCG, food processing, personal care, industrial goods, and export manufacturing will face a more demanding and tightly regulated environment. For many organisations, packaging will no longer be a support function. It will become a strategic performance driver that directly influences compliance, product integrity, and operational efficiency.

For businesses working with printing and packaging companies in Sri Lanka, understanding these emerging requirements early is essential to maintaining competitiveness and ensuring that packaging systems are aligned with future expectations.

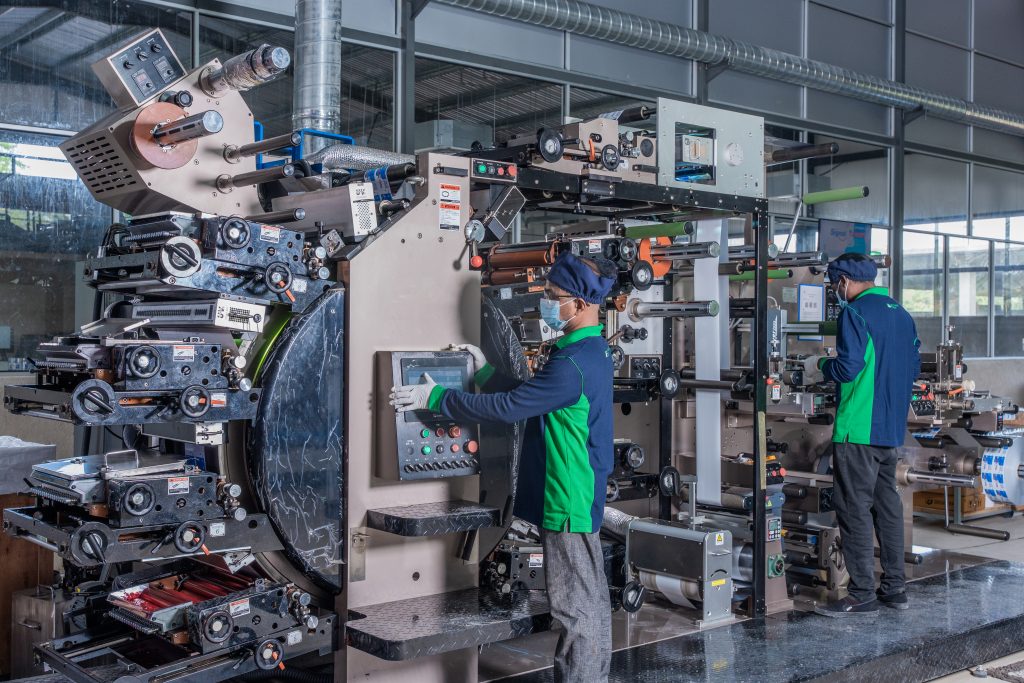

At JPI, we understand these changes and reinforce the importance of technology driven design, precision tooling and engineering led manufacturing as the foundation for next generation packaging performance.

Understanding the Global Shift

Across international markets, new policies targeting waste reduction, recyclability, traceability and material efficiency are reshaping expectations for packaging suppliers. Regions such as the EU, UK, and APAC are accelerating Extended Producer Responsibility (EPR) frameworks, mandatory reporting systems, and restrictions on non recyclable plastics.

For export focused brands, these standards will influence mold design, material selection, structural specifications and documentation requirements. By 2026, packaging formats that do not meet verifiable sustainability and performance criteria will face approval delays, additional testing or rejection in regulated markets.

Our integrated design and engineering capabilities enable early identification of compliance risks so that clients can move efficiently from concept to production with full awareness of upcoming global requirements.

The New Consumer Mindset

Regulations are tightening, but consumer expectations are advancing at the same pace. Buyers across B2B and B2C markets are more attentive to durability, hygiene, safety, and end of life impact. A recent McKinsey global packaging survey also confirms this shift, showing that consumers now prioritise sustainability, material transparency and product safety at levels significantly higher than before the pandemic. These behavioural changes directly influence packaging design and production decisions.

Key implications for packaging teams include

- Higher demand for lightweight yet structurally robust containers

- Increased preference for recyclable and mono-material solutions

- Stronger expectations for tamper-evidence and improved handling

- Greater interest in transparency around material origins and manufacturing methods

For B2B supply chains, these expectations translate into new performance benchmarks and packaging formats that must integrate reliably with automated filling, capping, and logistics systems.

We support these requirements by validating manufacturability early in the design process and engineering solutions that maintain stability in high volume production.

Meeting the Strict International Requirements

By 2026, export oriented brands will operate under a new level of scrutiny. Mandatory recyclability thresholds, detailed documentation for food contact compliance and stricter transport stress and shelf life requirements will become standard expectations. Companies will also need to provide clearer reporting structures tied to material origins and environmental impact, making compliance a continuous responsibility rather than a periodic task.

These evolving demands will directly influence how packaging is engineered. Mold structure and accuracy, material grades and compatibility, dimensional consistency and overall production stability will become non negotiable markers of reliability. For many brands, meeting these standards will require a level of technical precision that goes far beyond basic manufacturing.

Our in house mold making is designed to meet this rising complexity. This ensures accuracy, repeatability and compliance across large scale production allows clients to maintain confidence in consistent output. As global standards continue to evolve, this depth in engineering becomes a crucial advantage for brands operating in competitive export markets.

The Rise of Tech Enabled Manufacturing

Advanced molding systems, precision machining and engineering-driven monitoring are redefining modern packaging performance. Our technology remains central to how packaging solutions are developed and scaled.

Key advantages enabled by our tech driven manufacturing include

- Process optimised molding systems that improve cycle stability

- Data driven monitoring to maintain dimensional accuracy, wall thickness control, and clarity

- Precision tooling to minimise variance across high-volume batches

- Engineering led optimisation of material flow, cooling efficiency, and structural integrity

As brands evaluate printing and packaging companies in Sri Lanka, they will increasingly prioritise partners capable of integrating design, mold making, and engineering into a single quality-controlled system. Future packaging standards will reward technical readiness over reactive adjustments, an approach core to JPI’s operating philosophy.

Preparing Your Packaging Team Early

To meet 2026 expectations, internal packaging, procurement and R&D teams need to begin realignment now. This preparation starts with reviewing international regulatory timelines to understand what compliance will require in the coming years. From there, teams should assess their current packaging portfolios to identify sustainability gaps, performance weaknesses or areas that may fall short under new export standards.

A second focus is supplier capability. Engaging partners who are equipped for engineering driven development becomes essential, especially when accuracy, repeatability and material optimisation will determine whether packaging meets global expectations. This shift also demands stronger alignment between design, engineering, manufacturing and quality assurance. When these functions work cohesively, packaging systems become more resilient, consistent and scalable.

Our integrated workflow directly supports this early preparation. Their structured approach brings clarity during design validation, tooling development and production scaling, reducing redesign cycles and avoiding tooling delays. With this level of technical coordination, brands achieve faster readiness for regulated markets and enter 2026 with greater confidence and operational stability.

Building the Foundation for 2026 and Beyond

By 2026, brands will require packaging solutions engineered around regulatory precision, sustainability performance, and supply chain efficiency. These shifts create new opportunities and new responsibilities for manufacturers and suppliers.

JPI’s technology driven approach, backed by in house design, mold making and engineering capabilities, positions clients to navigate this transition with confidence.

With 2026 approaching, packaging will define not only product performance but brand competitiveness. The companies that invest in engineering precision today will be the ones who lead the next decade of manufacturing excellence.